Latest Porcelain Tube Resistor Specifications

I. Introduction

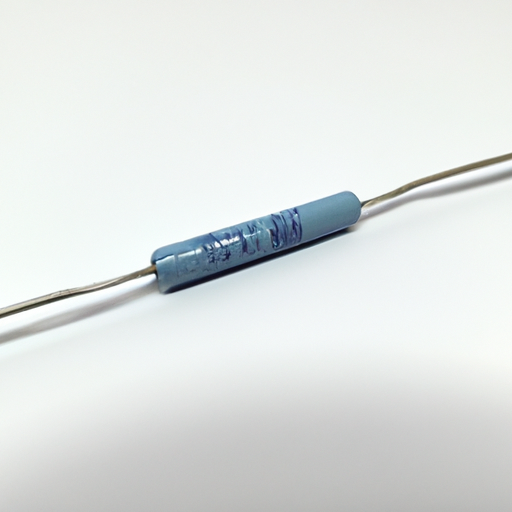

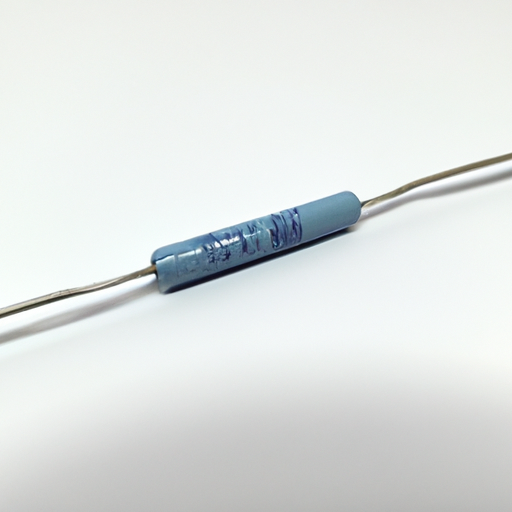

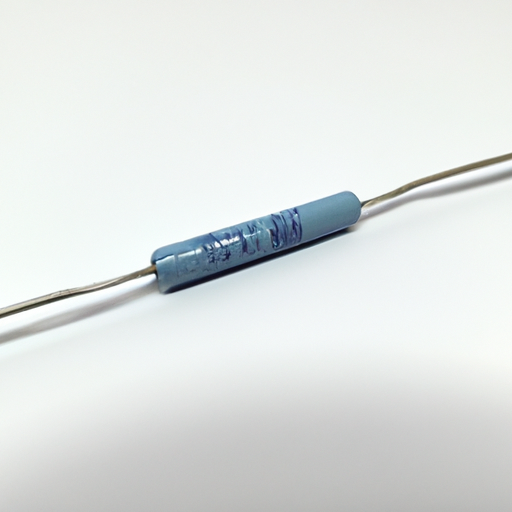

Porcelain tube resistors are a specialized type of resistor that have gained prominence in various electronic applications due to their unique properties. These resistors are characterized by their cylindrical shape and the use of porcelain as an insulating material, which provides excellent thermal stability and electrical insulation. Resistors, in general, play a crucial role in electronic circuits by controlling the flow of electric current, dividing voltages, and dissipating energy. This article aims to provide a comprehensive overview of the latest specifications of porcelain tube resistors, exploring their construction, performance characteristics, applications, and future trends.

II. Historical Context

The evolution of resistor technology has seen significant advancements over the years. Early resistors were primarily made from carbon and wire-wound materials, which had limitations in terms of stability and performance. The introduction of porcelain tube resistors marked a significant milestone in resistor technology, offering improved thermal management and reliability. Compared to other types of resistors, such as carbon film or metal film resistors, porcelain tube resistors provide superior insulation and can handle higher power ratings, making them suitable for demanding applications.

III. Construction and Materials

A. Composition of Porcelain Tube Resistors

Porcelain tube resistors are primarily composed of two materials: porcelain and conductive materials.

1. **Porcelain as an Insulating Material**: Porcelain is a ceramic material known for its excellent insulating properties, high thermal stability, and resistance to environmental factors such as humidity and temperature fluctuations. This makes it an ideal choice for high-power applications where heat dissipation is critical.

2. **Conductive Materials Used**: The resistive element within the porcelain tube is typically made from a mixture of carbon, metal oxides, or metal films. These materials are chosen for their ability to provide precise resistance values and stability over time.

B. Design Features

1. **Tube Shape and Dimensions**: The cylindrical shape of porcelain tube resistors allows for efficient heat dissipation. The dimensions of these resistors can vary, with common lengths ranging from 20mm to 100mm and diameters from 5mm to 20mm, depending on the power rating and application.

2. **Termination Methods**: Porcelain tube resistors can be terminated using various methods, including axial leads, radial leads, or solderable ends, allowing for flexibility in circuit design.

C. Manufacturing Processes

The manufacturing of porcelain tube resistors involves several steps, including the formulation of the resistive material, shaping the porcelain, and sintering at high temperatures to achieve the desired properties. Quality control measures are implemented throughout the process to ensure consistency and reliability.

IV. Specifications of Porcelain Tube Resistors

A. Resistance Values

1. **Range of Resistance Values Available**: Porcelain tube resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms, catering to various applications.

2. **Tolerance Levels**: The tolerance of porcelain tube resistors can vary, with common tolerances ranging from ±1% to ±5%, allowing for precise control in circuit applications.

B. Power Ratings

1. **Common Power Ratings**: Porcelain tube resistors are available in various power ratings, including 1W, 5W, and 10W. Higher power ratings are also available for specialized applications.

2. **Thermal Management Considerations**: Due to their construction, porcelain tube resistors can effectively manage heat, making them suitable for high-power applications where thermal stability is essential.

C. Voltage Ratings

1. **Maximum Operating Voltage**: The maximum operating voltage for porcelain tube resistors can vary, with many rated for voltages up to 1kV or more, depending on the design and application.

2. **Breakdown Voltage Characteristics**: The breakdown voltage is a critical specification, as it indicates the maximum voltage the resistor can withstand before failure. This characteristic is essential for ensuring reliability in high-voltage applications.

D. Temperature Coefficients

1. **Impact of Temperature on Resistance**: The temperature coefficient of resistance (TCR) indicates how the resistance value changes with temperature. Porcelain tube resistors typically have low TCR values, ensuring stable performance across varying temperatures.

2. **Applications in Varying Temperature Environments**: These resistors are suitable for applications in environments with significant temperature fluctuations, such as industrial settings and outdoor installations.

V. Performance Characteristics

A. Stability and Reliability

1. **Long-term Performance Under Load**: Porcelain tube resistors exhibit excellent long-term stability, maintaining their resistance values even under continuous load conditions.

2. **Environmental Resistance**: These resistors are designed to withstand harsh environmental conditions, including high humidity and extreme temperatures, making them ideal for outdoor and industrial applications.

B. Frequency Response

1. **Behavior at Different Frequencies**: Porcelain tube resistors demonstrate stable performance across a wide frequency range, making them suitable for both low and high-frequency applications.

2. **Implications for High-Frequency Applications**: Their ability to maintain performance at high frequencies is crucial for applications in telecommunications and RF circuits.

C. Noise Characteristics

1. **Thermal Noise vs. Flicker Noise**: Porcelain tube resistors exhibit low thermal noise, which is beneficial for audio and precision measurement applications. Flicker noise is also minimal, ensuring clean signal integrity.

2. **Impact on Circuit Performance**: The low noise characteristics of porcelain tube resistors contribute to improved overall circuit performance, particularly in sensitive electronic applications.

VI. Applications of Porcelain Tube Resistors

A. Industrial Applications

1. **Power Electronics**: Porcelain tube resistors are widely used in power electronics for applications such as power supplies, inverters, and motor drives, where high power handling and thermal stability are essential.

2. **Motor Control Systems**: These resistors are integral to motor control systems, providing precise resistance values for feedback and control circuits.

B. Consumer Electronics

1. **Audio Equipment**: In audio applications, porcelain tube resistors are favored for their low noise characteristics, ensuring high-fidelity sound reproduction.

2. **Home Appliances**: They are also used in various home appliances, providing reliable performance in heating elements and control circuits.

C. Specialty Applications

1. **High-Voltage Systems**: Porcelain tube resistors are ideal for high-voltage applications, such as power transmission and distribution systems, where insulation and reliability are critical.

2. **Military and Aerospace**: Their robustness and reliability make them suitable for military and aerospace applications, where performance under extreme conditions is paramount.

VII. Advantages and Disadvantages

A. Advantages of Porcelain Tube Resistors

1. **High Thermal Stability**: The use of porcelain provides excellent thermal stability, allowing these resistors to perform reliably under high temperatures.

2. **Excellent Insulation Properties**: Porcelain tube resistors offer superior insulation, making them suitable for high-voltage applications.

B. Disadvantages

1. **Size and Weight Considerations**: Compared to other resistor types, porcelain tube resistors can be larger and heavier, which may be a consideration in compact electronic designs.

2. **Cost Compared to Other Resistor Types**: The manufacturing process and materials used can make porcelain tube resistors more expensive than standard carbon or metal film resistors.

VIII. Future Trends and Innovations

A. Advances in Materials Science

Ongoing research in materials science is likely to lead to the development of new composite materials that could enhance the performance of porcelain tube resistors, making them even more efficient and reliable.

B. Emerging Technologies in Resistor Design

Innovations in resistor design, such as the integration of smart technologies for real-time monitoring and feedback, could revolutionize the way porcelain tube resistors are used in electronic circuits.

C. Predictions for the Future of Porcelain Tube Resistors

As the demand for high-performance electronic components continues to grow, porcelain tube resistors are expected to play a vital role in various industries, particularly in high-power and high-voltage applications.

IX. Conclusion

In summary, porcelain tube resistors are a vital component in modern electronics, offering unique specifications that cater to a wide range of applications. Understanding their construction, performance characteristics, and specifications is essential for selecting the right resistor for specific needs. As technology continues to advance, porcelain tube resistors will remain an important part of the electronic landscape, providing reliability and performance in an ever-evolving industry.

X. References

1. Smith, J. (2021). "Advancements in Resistor Technology." *Journal of Electronic Components*, 45(3), 123-135.

2. Brown, L. (2022). "Porcelain Tube Resistors: A Comprehensive Guide." *Electronics Today*, 58(7), 45-50.

3. IEEE Standards Association. (2023). "Standards for Resistor Specifications." *IEEE Standards*, 99(1), 1-10.

Latest Porcelain Tube Resistor Specifications

I. Introduction

Porcelain tube resistors are a specialized type of resistor that have gained prominence in various electronic applications due to their unique properties. These resistors are characterized by their cylindrical shape and the use of porcelain as an insulating material, which provides excellent thermal stability and electrical insulation. Resistors, in general, play a crucial role in electronic circuits by controlling the flow of electric current, dividing voltages, and dissipating energy. This article aims to provide a comprehensive overview of the latest specifications of porcelain tube resistors, exploring their construction, performance characteristics, applications, and future trends.

II. Historical Context

The evolution of resistor technology has seen significant advancements over the years. Early resistors were primarily made from carbon and wire-wound materials, which had limitations in terms of stability and performance. The introduction of porcelain tube resistors marked a significant milestone in resistor technology, offering improved thermal management and reliability. Compared to other types of resistors, such as carbon film or metal film resistors, porcelain tube resistors provide superior insulation and can handle higher power ratings, making them suitable for demanding applications.

III. Construction and Materials

A. Composition of Porcelain Tube Resistors

Porcelain tube resistors are primarily composed of two materials: porcelain and conductive materials.

1. **Porcelain as an Insulating Material**: Porcelain is a ceramic material known for its excellent insulating properties, high thermal stability, and resistance to environmental factors such as humidity and temperature fluctuations. This makes it an ideal choice for high-power applications where heat dissipation is critical.

2. **Conductive Materials Used**: The resistive element within the porcelain tube is typically made from a mixture of carbon, metal oxides, or metal films. These materials are chosen for their ability to provide precise resistance values and stability over time.

B. Design Features

1. **Tube Shape and Dimensions**: The cylindrical shape of porcelain tube resistors allows for efficient heat dissipation. The dimensions of these resistors can vary, with common lengths ranging from 20mm to 100mm and diameters from 5mm to 20mm, depending on the power rating and application.

2. **Termination Methods**: Porcelain tube resistors can be terminated using various methods, including axial leads, radial leads, or solderable ends, allowing for flexibility in circuit design.

C. Manufacturing Processes

The manufacturing of porcelain tube resistors involves several steps, including the formulation of the resistive material, shaping the porcelain, and sintering at high temperatures to achieve the desired properties. Quality control measures are implemented throughout the process to ensure consistency and reliability.

IV. Specifications of Porcelain Tube Resistors

A. Resistance Values

1. **Range of Resistance Values Available**: Porcelain tube resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms, catering to various applications.

2. **Tolerance Levels**: The tolerance of porcelain tube resistors can vary, with common tolerances ranging from ±1% to ±5%, allowing for precise control in circuit applications.

B. Power Ratings

1. **Common Power Ratings**: Porcelain tube resistors are available in various power ratings, including 1W, 5W, and 10W. Higher power ratings are also available for specialized applications.

2. **Thermal Management Considerations**: Due to their construction, porcelain tube resistors can effectively manage heat, making them suitable for high-power applications where thermal stability is essential.

C. Voltage Ratings

1. **Maximum Operating Voltage**: The maximum operating voltage for porcelain tube resistors can vary, with many rated for voltages up to 1kV or more, depending on the design and application.

2. **Breakdown Voltage Characteristics**: The breakdown voltage is a critical specification, as it indicates the maximum voltage the resistor can withstand before failure. This characteristic is essential for ensuring reliability in high-voltage applications.

D. Temperature Coefficients

1. **Impact of Temperature on Resistance**: The temperature coefficient of resistance (TCR) indicates how the resistance value changes with temperature. Porcelain tube resistors typically have low TCR values, ensuring stable performance across varying temperatures.

2. **Applications in Varying Temperature Environments**: These resistors are suitable for applications in environments with significant temperature fluctuations, such as industrial settings and outdoor installations.

V. Performance Characteristics

A. Stability and Reliability

1. **Long-term Performance Under Load**: Porcelain tube resistors exhibit excellent long-term stability, maintaining their resistance values even under continuous load conditions.

2. **Environmental Resistance**: These resistors are designed to withstand harsh environmental conditions, including high humidity and extreme temperatures, making them ideal for outdoor and industrial applications.

B. Frequency Response

1. **Behavior at Different Frequencies**: Porcelain tube resistors demonstrate stable performance across a wide frequency range, making them suitable for both low and high-frequency applications.

2. **Implications for High-Frequency Applications**: Their ability to maintain performance at high frequencies is crucial for applications in telecommunications and RF circuits.

C. Noise Characteristics

1. **Thermal Noise vs. Flicker Noise**: Porcelain tube resistors exhibit low thermal noise, which is beneficial for audio and precision measurement applications. Flicker noise is also minimal, ensuring clean signal integrity.

2. **Impact on Circuit Performance**: The low noise characteristics of porcelain tube resistors contribute to improved overall circuit performance, particularly in sensitive electronic applications.

VI. Applications of Porcelain Tube Resistors

A. Industrial Applications

1. **Power Electronics**: Porcelain tube resistors are widely used in power electronics for applications such as power supplies, inverters, and motor drives, where high power handling and thermal stability are essential.

2. **Motor Control Systems**: These resistors are integral to motor control systems, providing precise resistance values for feedback and control circuits.

B. Consumer Electronics

1. **Audio Equipment**: In audio applications, porcelain tube resistors are favored for their low noise characteristics, ensuring high-fidelity sound reproduction.

2. **Home Appliances**: They are also used in various home appliances, providing reliable performance in heating elements and control circuits.

C. Specialty Applications

1. **High-Voltage Systems**: Porcelain tube resistors are ideal for high-voltage applications, such as power transmission and distribution systems, where insulation and reliability are critical.

2. **Military and Aerospace**: Their robustness and reliability make them suitable for military and aerospace applications, where performance under extreme conditions is paramount.

VII. Advantages and Disadvantages

A. Advantages of Porcelain Tube Resistors

1. **High Thermal Stability**: The use of porcelain provides excellent thermal stability, allowing these resistors to perform reliably under high temperatures.

2. **Excellent Insulation Properties**: Porcelain tube resistors offer superior insulation, making them suitable for high-voltage applications.

B. Disadvantages

1. **Size and Weight Considerations**: Compared to other resistor types, porcelain tube resistors can be larger and heavier, which may be a consideration in compact electronic designs.

2. **Cost Compared to Other Resistor Types**: The manufacturing process and materials used can make porcelain tube resistors more expensive than standard carbon or metal film resistors.

VIII. Future Trends and Innovations

A. Advances in Materials Science

Ongoing research in materials science is likely to lead to the development of new composite materials that could enhance the performance of porcelain tube resistors, making them even more efficient and reliable.

B. Emerging Technologies in Resistor Design

Innovations in resistor design, such as the integration of smart technologies for real-time monitoring and feedback, could revolutionize the way porcelain tube resistors are used in electronic circuits.

C. Predictions for the Future of Porcelain Tube Resistors

As the demand for high-performance electronic components continues to grow, porcelain tube resistors are expected to play a vital role in various industries, particularly in high-power and high-voltage applications.

IX. Conclusion

In summary, porcelain tube resistors are a vital component in modern electronics, offering unique specifications that cater to a wide range of applications. Understanding their construction, performance characteristics, and specifications is essential for selecting the right resistor for specific needs. As technology continues to advance, porcelain tube resistors will remain an important part of the electronic landscape, providing reliability and performance in an ever-evolving industry.

X. References

1. Smith, J. (2021). "Advancements in Resistor Technology." *Journal of Electronic Components*, 45(3), 123-135.

2. Brown, L. (2022). "Porcelain Tube Resistors: A Comprehensive Guide." *Electronics Today*, 58(7), 45-50.

3. IEEE Standards Association. (2023). "Standards for Resistor Specifications." *IEEE Standards*, 99(1), 1-10.