The Latest Crane Resistor Wiring Diagram: Procurement Models of Equipment Components

I. Introduction

In the world of industrial machinery, cranes play a pivotal role in lifting and moving heavy loads. A critical component of crane operation is the resistor wiring diagram, which ensures that the electrical systems function correctly and safely. Understanding these diagrams is essential for operators, engineers, and maintenance personnel. However, the effectiveness of crane operations also hinges on the procurement models used for sourcing equipment components. This article aims to provide a comprehensive overview of crane resistor wiring diagrams and the various procurement models available for equipment components, highlighting their significance in optimizing crane performance.

II. Understanding Crane Resistor Wiring Diagrams

A. Definition and Function of Crane Resistors

Crane resistors are electrical components that manage the flow of current within a crane's control system. They are essential for controlling the speed of electric motors, providing braking functions, and ensuring the safe operation of the crane. By dissipating excess energy as heat, resistors help prevent damage to electrical components and enhance the overall safety of crane operations.

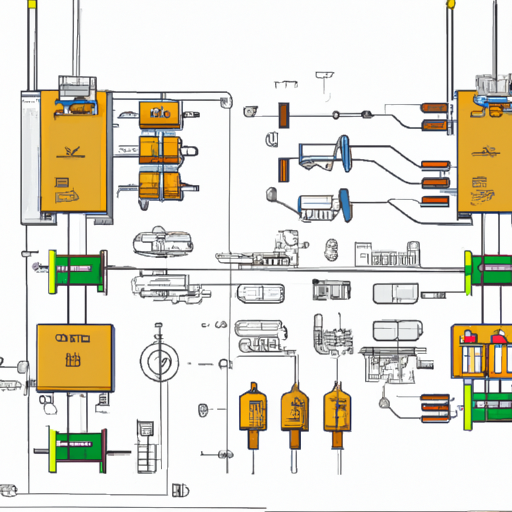

B. Components of a Typical Crane Resistor Wiring Diagram

A typical crane resistor wiring diagram includes several key components:

1. **Resistors**: These are the primary components that regulate electrical current.

2. **Connectors**: These facilitate the connection between various electrical components, ensuring a seamless flow of electricity.

3. **Control Systems**: These systems manage the operation of the crane, including speed control and braking mechanisms.

C. Importance of Accurate Wiring Diagrams in Crane Operation

Accurate wiring diagrams are crucial for several reasons. They provide a clear visual representation of the electrical system, making it easier for technicians to troubleshoot issues and perform maintenance. Additionally, they ensure compliance with safety standards, reducing the risk of electrical failures that could lead to accidents or equipment damage.

III. Types of Crane Resistor Wiring Diagrams

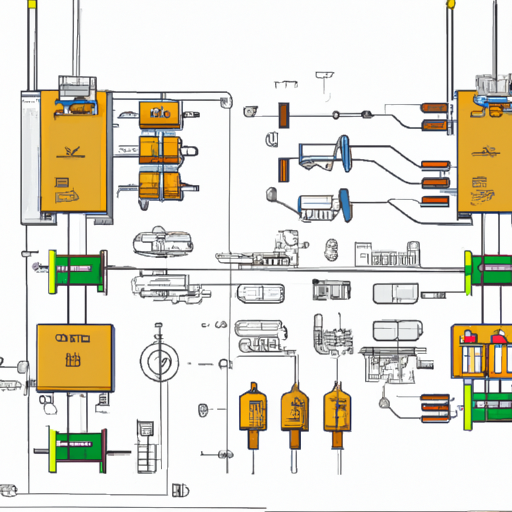

A. Basic Wiring Diagrams

Basic wiring diagrams offer a simplified view of the electrical connections within a crane. They are useful for quick reference and understanding the general layout of the system.

B. Detailed Schematic Diagrams

Detailed schematic diagrams provide a more in-depth look at the electrical components and their interconnections. These diagrams are essential for technicians who need to diagnose complex issues or perform repairs.

C. Block Diagrams

Block diagrams present a high-level overview of the crane's electrical system, illustrating the main components and their functions without delving into intricate details. They are useful for understanding the overall system architecture.

D. Comparison of Different Types

While basic wiring diagrams are suitable for quick reference, detailed schematic diagrams are necessary for troubleshooting and repairs. Block diagrams, on the other hand, are ideal for understanding the system's functionality at a glance. Each type of diagram serves a specific purpose, and having access to all three can enhance operational efficiency.

IV. Procurement Models for Equipment Components

A. Definition of Procurement Models

Procurement models refer to the strategies and processes used to acquire equipment components. Selecting the right procurement model is crucial for ensuring that the necessary components are available when needed, at the right price, and of the required quality.

B. Importance of Selecting the Right Procurement Model

The choice of procurement model can significantly impact the efficiency and cost-effectiveness of crane operations. A well-chosen model can lead to reduced lead times, improved supplier relationships, and enhanced overall performance.

C. Overview of Common Procurement Models

1. **Direct Purchase**

- **Description**: This model involves purchasing components directly from suppliers as needed.

- **Advantages**: Offers flexibility and immediate access to components.

- **Disadvantages**: May lead to higher costs and longer lead times if not managed properly.

2. **Just-In-Time (JIT) Procurement**

- **Description**: JIT procurement focuses on receiving components only as they are needed in the production process.

- **Advantages**: Reduces inventory costs and minimizes waste.

- **Disadvantages**: Requires precise coordination with suppliers and can lead to production delays if components are not delivered on time.

3. **Vendor-Managed Inventory (VMI)**

- **Description**: In this model, the supplier manages the inventory levels of components on behalf of the buyer.

- **Advantages**: Reduces the burden on the buyer to manage inventory and can lead to cost savings.

- **Disadvantages**: Relies heavily on the supplier's ability to forecast demand accurately.

4. **Consignment Stock**

- **Description**: Components are stored at the buyer's location but remain the property of the supplier until used.

- **Advantages**: Reduces upfront costs and inventory risk for the buyer.

- **Disadvantages**: Requires a strong relationship with the supplier and clear agreements on inventory management.

5. **Group Purchasing Organizations (GPO)**

- **Description**: GPOs leverage the collective buying power of multiple organizations to negotiate better prices and terms with suppliers.

- **Advantages**: Can lead to significant cost savings and improved supplier relationships.

- **Disadvantages**: May limit flexibility in choosing suppliers and components.

V. Factors Influencing Procurement Decisions

Several factors influence procurement decisions for crane components:

A. Cost Considerations

Cost is often the primary factor in procurement decisions. Organizations must balance the need for quality components with budget constraints.

B. Quality and Reliability of Components

The quality and reliability of components are critical for ensuring safe and efficient crane operations. Organizations must evaluate suppliers based on their track record and the quality of their products.

C. Supplier Relationships

Strong relationships with suppliers can lead to better pricing, improved service, and more reliable delivery schedules. Organizations should prioritize building and maintaining these relationships.

D. Lead Times and Delivery Schedules

Timely delivery of components is essential for minimizing downtime and ensuring smooth operations. Organizations must consider lead times when selecting procurement models and suppliers.

E. Regulatory Compliance and Standards

Compliance with industry regulations and standards is non-negotiable. Organizations must ensure that all components meet the necessary safety and quality standards.

VI. Best Practices in Procurement for Crane Components

To optimize procurement for crane components, organizations should follow these best practices:

A. Conducting Thorough Market Research

Understanding the market landscape is crucial for identifying reliable suppliers and competitive pricing.

B. Establishing Clear Specifications

Clear specifications help ensure that the right components are procured, reducing the risk of errors and mismatches.

C. Evaluating Suppliers

Organizations should conduct thorough evaluations of potential suppliers, considering factors such as quality, reliability, and service.

D. Negotiating Contracts

Effective negotiation can lead to better pricing and terms, benefiting both parties in the long run.

E. Monitoring and Managing Supplier Performance

Regularly monitoring supplier performance helps organizations identify potential issues early and maintain strong relationships.

VII. Case Studies

A. Example of Successful Procurement Model Implementation

A construction company implemented a JIT procurement model for its crane components, resulting in a 20% reduction in inventory costs and improved operational efficiency. By closely coordinating with suppliers, the company minimized delays and ensured that components were available when needed.

B. Lessons Learned from Procurement Failures

A manufacturing firm experienced significant downtime due to delays in component delivery. The company had relied on a direct purchase model without establishing strong supplier relationships. This highlighted the importance of evaluating procurement models and maintaining open communication with suppliers.

C. Impact of Procurement Decisions on Crane Operations

Effective procurement decisions can lead to enhanced crane performance, reduced downtime, and improved safety. Conversely, poor procurement choices can result in costly delays and operational inefficiencies.

VIII. Conclusion

In conclusion, understanding crane resistor wiring diagrams and the various procurement models for equipment components is essential for optimizing crane operations. Accurate wiring diagrams ensure safe and efficient operation, while the right procurement model can significantly impact cost, quality, and delivery. Industry professionals are encouraged to enhance their procurement strategies by considering the factors discussed in this article, ultimately leading to improved crane performance and safety.

IX. References

- [Crane Safety Standards](https://www.osha.gov)

- [Electrical Wiring Diagrams](https://www.electricalengineering.org)

- [Procurement Best Practices](https://www.procurementleaders.com)

- [Just-In-Time Manufacturing](https://www.jit.com)

- [Vendor-Managed Inventory](https://www.vmi.com)

By following the insights and best practices outlined in this article, organizations can ensure that their crane operations are not only efficient but also safe and compliant with industry standards.

The Latest Crane Resistor Wiring Diagram: Procurement Models of Equipment Components

I. Introduction

In the world of industrial machinery, cranes play a pivotal role in lifting and moving heavy loads. A critical component of crane operation is the resistor wiring diagram, which ensures that the electrical systems function correctly and safely. Understanding these diagrams is essential for operators, engineers, and maintenance personnel. However, the effectiveness of crane operations also hinges on the procurement models used for sourcing equipment components. This article aims to provide a comprehensive overview of crane resistor wiring diagrams and the various procurement models available for equipment components, highlighting their significance in optimizing crane performance.

II. Understanding Crane Resistor Wiring Diagrams

A. Definition and Function of Crane Resistors

Crane resistors are electrical components that manage the flow of current within a crane's control system. They are essential for controlling the speed of electric motors, providing braking functions, and ensuring the safe operation of the crane. By dissipating excess energy as heat, resistors help prevent damage to electrical components and enhance the overall safety of crane operations.

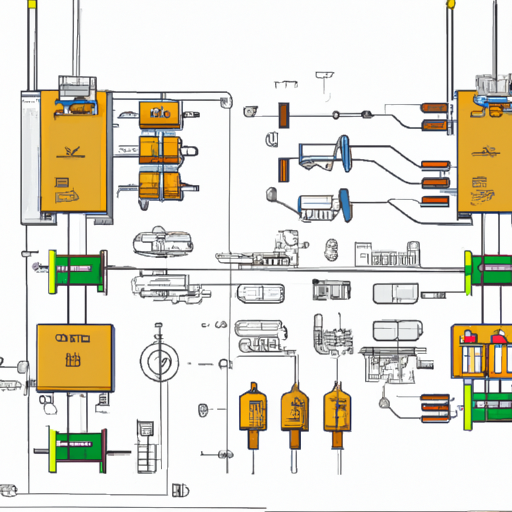

B. Components of a Typical Crane Resistor Wiring Diagram

A typical crane resistor wiring diagram includes several key components:

1. **Resistors**: These are the primary components that regulate electrical current.

2. **Connectors**: These facilitate the connection between various electrical components, ensuring a seamless flow of electricity.

3. **Control Systems**: These systems manage the operation of the crane, including speed control and braking mechanisms.

C. Importance of Accurate Wiring Diagrams in Crane Operation

Accurate wiring diagrams are crucial for several reasons. They provide a clear visual representation of the electrical system, making it easier for technicians to troubleshoot issues and perform maintenance. Additionally, they ensure compliance with safety standards, reducing the risk of electrical failures that could lead to accidents or equipment damage.

III. Types of Crane Resistor Wiring Diagrams

A. Basic Wiring Diagrams

Basic wiring diagrams offer a simplified view of the electrical connections within a crane. They are useful for quick reference and understanding the general layout of the system.

B. Detailed Schematic Diagrams

Detailed schematic diagrams provide a more in-depth look at the electrical components and their interconnections. These diagrams are essential for technicians who need to diagnose complex issues or perform repairs.

C. Block Diagrams

Block diagrams present a high-level overview of the crane's electrical system, illustrating the main components and their functions without delving into intricate details. They are useful for understanding the overall system architecture.

D. Comparison of Different Types

While basic wiring diagrams are suitable for quick reference, detailed schematic diagrams are necessary for troubleshooting and repairs. Block diagrams, on the other hand, are ideal for understanding the system's functionality at a glance. Each type of diagram serves a specific purpose, and having access to all three can enhance operational efficiency.

IV. Procurement Models for Equipment Components

A. Definition of Procurement Models

Procurement models refer to the strategies and processes used to acquire equipment components. Selecting the right procurement model is crucial for ensuring that the necessary components are available when needed, at the right price, and of the required quality.

B. Importance of Selecting the Right Procurement Model

The choice of procurement model can significantly impact the efficiency and cost-effectiveness of crane operations. A well-chosen model can lead to reduced lead times, improved supplier relationships, and enhanced overall performance.

C. Overview of Common Procurement Models

1. **Direct Purchase**

- **Description**: This model involves purchasing components directly from suppliers as needed.

- **Advantages**: Offers flexibility and immediate access to components.

- **Disadvantages**: May lead to higher costs and longer lead times if not managed properly.

2. **Just-In-Time (JIT) Procurement**

- **Description**: JIT procurement focuses on receiving components only as they are needed in the production process.

- **Advantages**: Reduces inventory costs and minimizes waste.

- **Disadvantages**: Requires precise coordination with suppliers and can lead to production delays if components are not delivered on time.

3. **Vendor-Managed Inventory (VMI)**

- **Description**: In this model, the supplier manages the inventory levels of components on behalf of the buyer.

- **Advantages**: Reduces the burden on the buyer to manage inventory and can lead to cost savings.

- **Disadvantages**: Relies heavily on the supplier's ability to forecast demand accurately.

4. **Consignment Stock**

- **Description**: Components are stored at the buyer's location but remain the property of the supplier until used.

- **Advantages**: Reduces upfront costs and inventory risk for the buyer.

- **Disadvantages**: Requires a strong relationship with the supplier and clear agreements on inventory management.

5. **Group Purchasing Organizations (GPO)**

- **Description**: GPOs leverage the collective buying power of multiple organizations to negotiate better prices and terms with suppliers.

- **Advantages**: Can lead to significant cost savings and improved supplier relationships.

- **Disadvantages**: May limit flexibility in choosing suppliers and components.

V. Factors Influencing Procurement Decisions

Several factors influence procurement decisions for crane components:

A. Cost Considerations

Cost is often the primary factor in procurement decisions. Organizations must balance the need for quality components with budget constraints.

B. Quality and Reliability of Components

The quality and reliability of components are critical for ensuring safe and efficient crane operations. Organizations must evaluate suppliers based on their track record and the quality of their products.

C. Supplier Relationships

Strong relationships with suppliers can lead to better pricing, improved service, and more reliable delivery schedules. Organizations should prioritize building and maintaining these relationships.

D. Lead Times and Delivery Schedules

Timely delivery of components is essential for minimizing downtime and ensuring smooth operations. Organizations must consider lead times when selecting procurement models and suppliers.

E. Regulatory Compliance and Standards

Compliance with industry regulations and standards is non-negotiable. Organizations must ensure that all components meet the necessary safety and quality standards.

VI. Best Practices in Procurement for Crane Components

To optimize procurement for crane components, organizations should follow these best practices:

A. Conducting Thorough Market Research

Understanding the market landscape is crucial for identifying reliable suppliers and competitive pricing.

B. Establishing Clear Specifications

Clear specifications help ensure that the right components are procured, reducing the risk of errors and mismatches.

C. Evaluating Suppliers

Organizations should conduct thorough evaluations of potential suppliers, considering factors such as quality, reliability, and service.

D. Negotiating Contracts

Effective negotiation can lead to better pricing and terms, benefiting both parties in the long run.

E. Monitoring and Managing Supplier Performance

Regularly monitoring supplier performance helps organizations identify potential issues early and maintain strong relationships.

VII. Case Studies

A. Example of Successful Procurement Model Implementation

A construction company implemented a JIT procurement model for its crane components, resulting in a 20% reduction in inventory costs and improved operational efficiency. By closely coordinating with suppliers, the company minimized delays and ensured that components were available when needed.

B. Lessons Learned from Procurement Failures

A manufacturing firm experienced significant downtime due to delays in component delivery. The company had relied on a direct purchase model without establishing strong supplier relationships. This highlighted the importance of evaluating procurement models and maintaining open communication with suppliers.

C. Impact of Procurement Decisions on Crane Operations

Effective procurement decisions can lead to enhanced crane performance, reduced downtime, and improved safety. Conversely, poor procurement choices can result in costly delays and operational inefficiencies.

VIII. Conclusion

In conclusion, understanding crane resistor wiring diagrams and the various procurement models for equipment components is essential for optimizing crane operations. Accurate wiring diagrams ensure safe and efficient operation, while the right procurement model can significantly impact cost, quality, and delivery. Industry professionals are encouraged to enhance their procurement strategies by considering the factors discussed in this article, ultimately leading to improved crane performance and safety.

IX. References

- [Crane Safety Standards](https://www.osha.gov)

- [Electrical Wiring Diagrams](https://www.electricalengineering.org)

- [Procurement Best Practices](https://www.procurementleaders.com)

- [Just-In-Time Manufacturing](https://www.jit.com)

- [Vendor-Managed Inventory](https://www.vmi.com)

By following the insights and best practices outlined in this article, organizations can ensure that their crane operations are not only efficient but also safe and compliant with industry standards.